Advanced manufacturing

School of Manufacturing, Systems and Networks

The academic programs and research portfolio of the School of Manufacturing Systems and Networks are designed to address the next-generation engineering challenges transforming manufacturing systems. Through real-world curriculum, research excellence and opportunities for comprehensive partnerships, graduates have the skills needed to impact the future of work, including industry 4.0, autonomous systems and processes, and systems engineering.

- Dedicated to keeping students, faculty and industry partners at the forefront of manufacturing technology and innovation.

- Designing and prototyping new production testbeds, materials and software that can attend to the demand for production of increasingly complex parts and products characterized as multi-phased, multi-scale and multi-functional.

- Addressing problems in an interdisciplinary ecosystem with additive and subtractive manufacturing.

- Continuous fiber 3D printing.

- Fused deposition modeling.

- Material jetting.

- Metal selective laser melting.

- Selective laser sintering.

- Stereolithography.

- Wire EDM (post-processing).

The ASU advantage

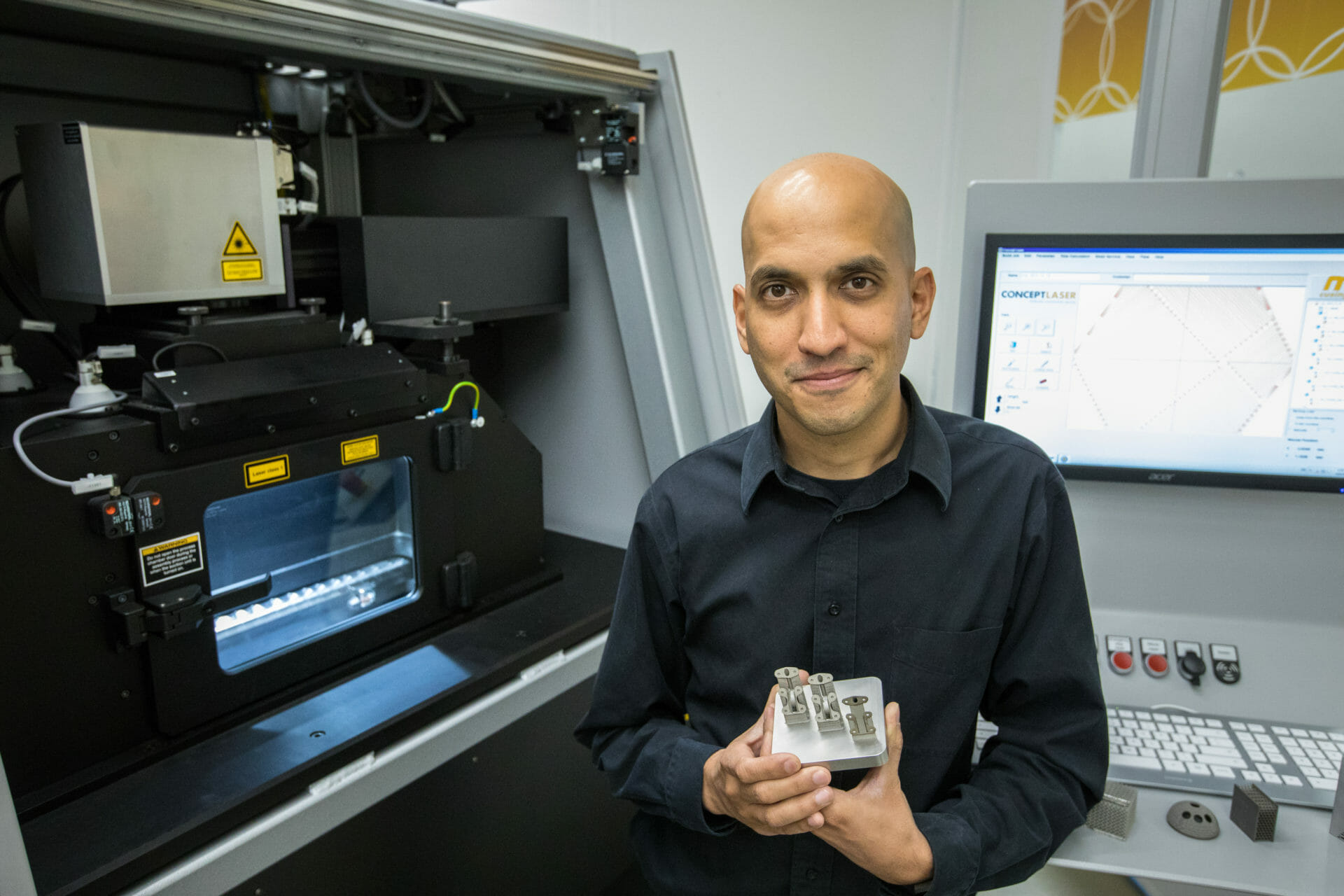

ASU is home to the largest additive manufacturing R&D center at a university in the Southwest. Established with a $2M investment and support from Honeywell Aerospace, Concept Laser Inc. (now GE Additive), Stratasys Inc., PADT Inc. and Intel Corporation, the Manufacturing Innovation Center has over 20 3D Printers that fabricate parts in polymers, composites and metal.

In addition, ASU is home to several manufacturing capabilities including additive manufacturing (3D printing), CNC manufacturing and welding, microscopy tools, and more.

Key research areas

- Process-structure-property relationship and modeling.

- Additive manufacturing process modeling (selective laser melting).

- Hybrid additive manufacturing process development.

- Process innovation.

- Mesoscale composites’ manufacturing.

- Micro- and nano-scale 3D printing.

- Nanostructured feedstock for metal additive manufacturing.

Manufacturing the future

The Manufacturing Innovation Center brings people and ideas together to solve the industry’s manufacturing problems and to develop future manufacturing and materials technologies. Here students are trained to become future leaders, engineers, researchers, innovators and entrepreneurs.

MacroTechnology Works is a world-class research facility that allows ASU to advance research in partnership with private industry. This facility offers access to a semiconductor processing facility, advanced electronics and photonics facility, and also offers clean rooms, wet labs, dry labs, high bay space and office accommodations.

AZNext is a public-private partnership designed to create a bold and sustaining workforce development ecosystem that addresses the need for more skilled workers in advanced manufacturing roles.

With an investment by the state, ASU is committed to leveraging knowledge and expertise to improve Arizona’s competitiveness in sectors that matter most for industrial growth, including advanced manufacturing.

As a result, the Advanced Manufacturing Science and Technology Center is an engine driving Arizona manufacturing innovation as partners leverage center capabilities and expertise and engage with students.

10 degree programs that enable a concentration in manufacturing

Four state-of-the-art manufacturing research laboratories

Advanced Manufacturing

Download a printable version of this webpage.

Get in touch with questions and comments

ASU Economic Development is here to be your partner, your resource and your advocate. Contact us today for a personal consultation.